TCR Engineering Approved for India's Landmark High Speed Rail Project Testing

- Jan 12

- 11 min read

Updated: Feb 24

When India embarked on its most ambitious transportation infrastructure project—the Mumbai-Ahmedabad High Speed Rail corridor that will bring Japanese bullet train technology to Indian tracks—the question of quality assurance became paramount. At speeds reaching 320 km/h, there's zero margin for error in materials, construction quality, or testing verification. Every component, from track fasteners to structural concrete, requires validation against the most stringent international standards. For TCR Engineering, securing approval from the National High Speed Rail Corporation Limited (NHSRCL) to provide testing services for this landmark project represents both recognition of technical excellence and responsibility for ensuring the safety of millions of future passengers.

Here's what most people don't realise about infrastructure projects of this magnitude. The Mumbai-Ahmedabad High Speed Rail isn't just another railway line—it's India's entry into an elite club of nations operating bullet train systems where Japanese precision engineering meets Indian construction realities. The 508-kilometer corridor traversing Gujarat and Maharashtra will slash travel time from eight hours to under three hours, but only if every single material and component performs flawlessly for decades. This is why NHSRCL's vendor approval process is so rigorous, and why securing that approval required demonstrating capabilities that separate world-class testing facilities from ordinary laboratories.

The Approval That Opens India's Infrastructure Future

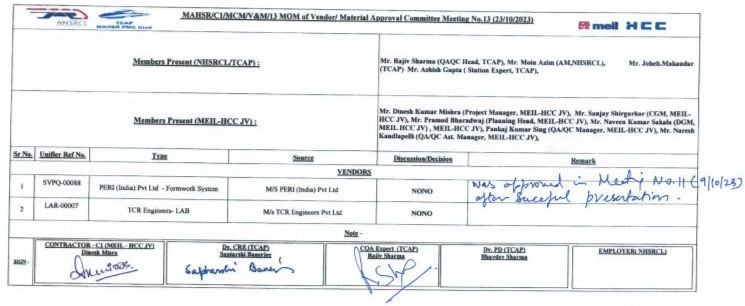

Hemant Sakpal, Business Development Manager at TCR Engineering, led the strategic initiative that secured the laboratory's approval for High Speed Rail testing services. His understanding of what NHSRCL's Vendor Material Approval Committee demands—combined with TCR's proven technical capabilities—culminated in formal approval during VMAC Meeting No. 13 held on October 23, 2023, for Package C1 executed by Megha Engineering & Infrastructures Ltd. in joint venture with HCC (MEIL-HCC JV).

The approval process wasn't a simple paperwork exercise. It required a comprehensive technical presentation before NHSRCL's quality assurance heads, TCAP (Track, Civil and Allied works Package) station experts, and the package contractor's senior management team. The meeting, documented in official Minutes of Meeting that serve as the contractual record of vendor approvals, evaluated TCR's equipment capabilities, testing procedures, quality management systems, and experience with international standards that high-speed rail construction demands.

What makes this approval particularly significant is NHSRCL's approach to vendor qualification. Unlike conventional projects where laboratories might receive standalone approval letters, NHSRCL's system integrates vendor approvals directly into package-specific VMAC meetings. This ensures that approved laboratories understand the exact requirements, testing standards, and quality expectations for the specific work packages they'll support. TCR's approval through this rigorous process validates that the laboratory meets the exacting standards India's first bullet train project requires.

Continuous Engagement Across Multiple HSR Packages

Since March 2024, TCR Engineering has been continuously engaged for testing services across three major Mumbai-Ahmedabad High Speed Rail packages, reflecting the sustained confidence that contractors and NHSRCL place in the laboratory's capabilities. This isn't one-time project testing—it's ongoing quality assurance support for massive civil construction packages that will form the backbone of India's high-speed rail network.

Package C1, executed by MEIL-HCC Joint Venture, represents the initial approval where TCR demonstrated its capabilities. The successful delivery of testing services on this package opened doors to additional engagements. Package C2, under Afcons Infrastructure Ltd., expanded TCR's role in the project. Package C3, awarded to Larsen & Toubro, further demonstrates the laboratory's growing footprint across the High Speed Rail corridor.

Hemant Sakpal's business development strategy recognises that infrastructure projects of this scale require more than just technical capability—they demand the capacity to support multiple major contractors simultaneously, maintain consistent quality across different package requirements, and provide the rapid turnaround that construction schedules demand. TCR's engagement across three packages simultaneously proves the laboratory possesses this operational capability that separates comprehensive testing facilities from those that can only handle limited workloads.

What High Speed Rail Testing Actually Involves

The materials testing requirements for high-speed rail construction differ dramatically from conventional railway projects. Track systems designed for 320 km/h operation face forces and stresses that would destroy conventional infrastructure. Concrete structures supporting elevated viaducts must maintain dimensional stability and strength for decades while resisting vibration, thermal cycling, and environmental exposure. Fastening systems securing rails to track slabs demand precision and durability that conventional fasteners can't match.

TCR Engineering's testing scope for High Speed Rail packages encompasses the comprehensive material characterisation and quality verification that these demanding applications require. Civil construction materials including concrete, reinforcement steel, and structural components undergo testing per international standards that govern high-speed rail construction globally. Track work materials face evaluation protocols ensuring they meet the Japanese Shinkansen-derived specifications that NHSRCL has adapted for Indian conditions.

The testing operates on compressed timelines that construction schedules dictate. Batch testing of concrete must deliver results within hours so placement can proceed. Material qualification testing must complete rapidly enough that supply chains don't experience delays. Yet speed cannot compromise accuracy—a single material failure in high-speed rail service could cause catastrophic derailment. TCR's systems balance these competing demands through efficient laboratory workflows, sufficient equipment capacity, and experienced technical staff who understand what HSR construction requires.

The Mumbai-Ahmedabad High Speed Rail Corridor

The 508-kilometer Mumbai-Ahmedabad High Speed Rail corridor represents India's most technically ambitious infrastructure project currently under construction. The alignment traverses two states—Gujarat and Maharashtra—connecting India's financial capital with its premier industrial hub through 12 stations including major stops at Surat, Vadodara, and Ahmedabad. The project employs Japanese Shinkansen technology under the Make in India framework, combining international expertise with Indian engineering and construction capabilities.

Design speeds of 320 km/h on the standard gauge (1435mm) alignment will enable the journey in under three hours compared to current seven-eight hour travel times. The infrastructure includes extensive elevated viaduct sections, major river crossings, and complex urban interfaces at Mumbai and Ahmedabad terminals. Civil construction packages covering these diverse requirements create varied testing demands that laboratories must accommodate.

Package C1, where TCR received initial approval, covers specific corridor sections with their unique geological, environmental, and construction challenges. Package C2 and Package C3 encompass different alignment sections, each with distinct material requirements and testing protocols. Hemant Sakpal's success in securing testing engagements across all three packages demonstrates TCR's ability to adapt testing capabilities to varied package specifications while maintaining the consistent quality that NHSRCL demands.

The Technical Presentation That Secured Approval

VMAC Meeting No. 13 on October 23, 2023, wasn't just a formality—it was a rigorous technical evaluation where TCR Engineering demonstrated why its Mahape, Navi Mumbai laboratory deserved approval for high-speed rail testing. The presentation covered equipment capabilities, testing procedures, quality management systems, accreditations, experience with similar projects, and capacity to handle the workload HSR packages generate.

Committee members including NHSRCL's QAQC Head, Assistant Manager, TCAP Station Expert, and senior representatives from MEIL-HCC JV evaluated every aspect of TCR's capabilities. The discussion addressed specific testing requirements, turnaround times, reporting formats, coordination procedures, and quality documentation that HSR construction demands. Only after satisfactory responses to all queries did the committee accord approval, documented in the official MoM that serves as the contractual record.

This approval process reflects NHSRCL's commitment to ensuring that only genuinely qualified laboratories support High Speed Rail construction. The scrutiny prevents the quality compromises that plague some Indian infrastructure projects where inadequate testing allows substandard materials into critical applications. For TCR, successfully navigating this rigorous approval validates years of investment in equipment, personnel training, quality systems, and technical expertise that world-class testing facilities require.

Why NHSRCL's Approval System Ensures Quality

NHSRCL's approach of integrating vendor approvals into package-specific VMAC meetings, rather than issuing standalone approval letters, creates tighter quality control than conventional approval systems. Laboratories approved for specific packages understand exactly what those packages require—testing standards, sample frequencies, reporting formats, coordination procedures, and acceptance criteria. This package-specific approval prevents the confusion that occurs when laboratories receive generic approvals without understanding specific project requirements.

The Minutes of Meeting from VMAC sessions serve as official contractual records of approvals. Unlike standalone letters that might be ambiguous about scope or subject to varying interpretation, MoM documents capture the discussion, conditions, requirements, and agreed scope precisely. This documentation prevents disputes and ensures all parties—NHSRCL, contractors, and laboratories—share common understanding of what approval means and what deliverables are expected.

For manufacturers, contractors, and laboratories working on High Speed Rail packages, understanding this approval system is crucial. TCR Engineering's experience navigating NHSRCL's procedures—and securing approvals through formal VMAC processes—positions the laboratory as a knowledgeable partner for other organisations entering the HSR supply chain. Hemant Sakpal's expertise with these processes helps clients understand what NHSRCL requires and how to demonstrate compliance effectively.

The Business Development Strategy Behind HSR Success

Hemant Sakpal's approach to securing High Speed Rail testing engagements reflects sophisticated understanding that major infrastructure projects require long-term relationship building, not just responding to tender opportunities. His strategy involved early engagement with potential package contractors, understanding their testing requirements before construction began, demonstrating TCR's capabilities through facility visits and technical presentations, and establishing the relationships that convert into testing contracts when packages mobilise.

The success metrics go beyond just winning the initial approval. Continuous engagement across three packages since March 2024 demonstrates that TCR delivers the service quality that keeps contractors returning. In construction projects, testing laboratories that disappoint quickly lose business as contractors switch to more reliable alternatives. TCR's sustained engagement proves the laboratory meets the demanding requirements that HSR construction imposes.

Hemant Sakpal recognises that High Speed Rail testing represents not just current project revenue but positioning for India's future infrastructure development. The Mumbai-Ahmedabad corridor is just the beginning—multiple additional HSR corridors are planned connecting Delhi-Varanasi, Delhi-Ahmedabad, Mumbai-Nagpur, and other routes that will expand India's bullet train network over coming decades. Laboratories that succeed on the first corridor, building reputation for quality and reliability, position themselves as preferred partners for future projects.

What This Means for India's Infrastructure Quality

TCR Engineering's approval and ongoing engagement in High Speed Rail testing represents broader trends in Indian infrastructure quality evolution. World-class projects demand world-class quality systems, and that requires testing laboratories capable of meeting international standards rather than just satisfying minimal regulatory compliance. NHSRCL's rigorous vendor approval process, contractors' willingness to engage qualified laboratories, and the premium placed on testing excellence signal a maturing approach to infrastructure quality.

For the travelling public who will eventually ride these bullet trains at 320 km/h, laboratory approvals and testing protocols might seem like bureaucratic details. But these unsexy quality systems are exactly what ensures their safety. Every structural component, every track fastener, every material in the corridor has been tested and verified against specifications derived from decades of Shinkansen operational experience. This systematic quality assurance is why Japanese bullet trains have operated for 60 years without a single passenger fatality from derailment.

The Mumbai-Ahmedabad High Speed Rail corridor, when operational, will demonstrate that India can build and operate infrastructure meeting the highest global standards. Behind that achievement will be thousands of testing verifications, quality checks, and material inspections that prevented defects from entering the construction. TCR Engineering's role in this quality assurance, secured through Hemant Sakpal's business development efforts and validated through rigorous NHSRCL approval, contributes to the safety and reliability that will define India's entry into the elite club of high-speed rail nations.

The Documentation That Proves Engagement

For organisations requiring verification of TCR's High Speed Rail approval—whether for partnering opportunities, compliance documentation, or due diligence—the laboratory provides copies of the relevant VMAC Meeting Minutes that officially record the approval. These MoM documents serve as the contractual record that NHSRCL's system relies upon, providing unambiguous proof of approval status and scope.

Additionally, TCR can present purchase orders and engagement records from the three package contractors—MEIL-HCC JV (Package C1), Afcons Infrastructure Ltd. (Package C2), and Larsen & Toubro (Package C3)—documenting continuous testing services since March 2024. This engagement history demonstrates not just approval but active, ongoing involvement in HSR construction that validates the laboratory's capabilities through actual project delivery rather than just paper qualifications.

This documentation transparency reflects Hemant Sakpal's approach to business development built on verifiable credentials rather than vague claims. In an industry where some organisations exaggerate capabilities or misrepresent approvals, TCR's willingness to provide detailed documentation backing every claim builds the credibility that serious infrastructure projects demand.

Future Prospects: Expanding Role in India's HSR Network

The Mumbai-Ahmedabad corridor represents just the first phase of India's high-speed rail ambitions. Multiple additional corridors are in various stages of planning and development, each representing potential testing service opportunities for laboratories with proven HSR credentials. TCR's approval and successful delivery on the first corridor positions the laboratory advantageously for these future projects.

Hemant Sakpal's vision extends beyond current packages to the broader HSR network that will transform Indian transportation over coming decades. The relationships established with NHSRCL, experience gained understanding their requirements, and reputation built through successful delivery create competitive advantages as additional projects advance. Contractors and engineering firms entering the HSR space increasingly seek testing partners with demonstrated HSR experience rather than risking project delays with laboratories learning on the job.

The technical expertise TCR develops through HSR work—understanding bullet train specifications, rapid turnaround procedures, coordination with international consultants, and quality documentation systems—applies broadly across advanced infrastructure projects beyond just railways. Smart city developments, metro systems, expressways, and industrial facilities increasingly demand the same rigorous quality approaches that HSR requires. TCR's HSR credentials signal capabilities that these other advanced infrastructure applications need.

FAQs About HSR Testing Approval

Does TCR Engineering have official NHSRCL approval for High Speed Rail testing? Yes. TCR Engineering was approved during NHSRCL's Vendor Material Approval Committee Meeting No. 13 held on October 23, 2023, for Package C1. The approval is documented in the official Minutes of Meeting, which serves as the contractual record under NHSRCL's approval system. The laboratory has been continuously engaged for testing services across multiple HSR packages since March 2024.

Why doesn't NHSRCL issue standalone approval letters to laboratories? NHSRCL's system integrates vendor approvals into package-specific VMAC meetings rather than issuing standalone letters. The Minutes of Meeting from these sessions serve as official approval records. This approach ensures laboratories understand specific package requirements and creates clear documentation of approval scope and conditions.

Which High Speed Rail packages does TCR Engineering support? TCR Engineering provides testing services for Package C1 (MEIL-HCC JV), Package C2 (Afcons Infrastructure Ltd.), and Package C3 (Larsen & Toubro). This engagement across three major civil packages demonstrates the laboratory's capacity to support multiple contractors simultaneously.

What testing does TCR perform for High Speed Rail construction? Testing scope encompasses civil construction materials including concrete, reinforcement steel, and structural components, along with track work materials and components. All testing follows international standards and specifications that NHSRCL requires for high-speed rail construction meeting Japanese Shinkansen-derived requirements.

Can TCR provide documentation of its HSR approval? Yes. TCR provides copies of the VMAC Meeting Minutes officially recording the approval, along with purchase orders and engagement records from package contractors documenting continuous testing services since March 2024. This documentation serves for compliance verification, partnering opportunities, or due diligence purposes.

How does TCR's HSR approval benefit manufacturers and contractors? Working with an NHSRCL-approved laboratory streamlines material qualification and quality documentation. TCR understands HSR requirements, coordinate effectively with contractors and NHSRCL, and provides testing data in formats that project specifications demand. This reduces qualification delays and documentation issues.

Is TCR's approval limited to specific geographic sections of the corridor? TCR's engagement spans multiple packages covering different corridor sections, demonstrating capability to support work along the entire Mumbai-Ahmedabad alignment. The laboratory's Mahape, Navi Mumbai location provides convenient access for contractors working on Maharashtra sections while serving Gujarat packages as well.

Who should organisations contact at TCR about High Speed Rail testing services? Hemant Sakpal, Business Development Manager at TCR Engineering, leads the laboratory's High Speed Rail engagement. He can discuss testing requirements, approval documentation, service scope, and coordination procedures for organisations requiring HSR testing support.

TCR Engineering's approval for India's Mumbai-Ahmedabad High Speed Rail project testing, secured through NHSRCL's rigorous Vendor Material Approval Committee process and documented in official VMAC Meeting Minutes, positions the Mahape, Navi Mumbai laboratory as a key quality assurance partner for India's most ambitious transportation infrastructure initiative. Under Hemant Sakpal's business development leadership, the laboratory has translated this approval into continuous testing engagement across three major HSR packages—C1 (MEIL-HCC JV), C2 (Afcons Infrastructure), and C3 (Larsen & Toubro)—since March 2024, demonstrating the sustained performance that keeps contractors returning for the rigorous materials testing that 320 km/h bullet train construction demands. As India embarks on expanding its high-speed rail network with multiple additional corridors planned connecting major cities across the country, TCR's proven credentials and successful delivery on the first corridor establish the laboratory as a trusted testing partner for the advanced infrastructure projects that will define India's transportation future, ensuring that the materials, components, and construction quality meet the uncompromising standards required when millions of passengers will travel at speeds where engineering excellence and quality assurance literally mean the difference between world-class success and catastrophic failure.